Aircraft stands' now inspected with lasers and AI

After a successful trial, Mavisoft, SWIC, VolkerInfra and Schiphol are entering a 5-year collaboration to inspect the concrete pavement of aircraft stands in an innovative manner. The most important outcome of this innovation is the extension of the concrete paving’s lifespan. This increases the availability of the aircraft stands while minimising costs, hindrance, materials and CO2 emissions.

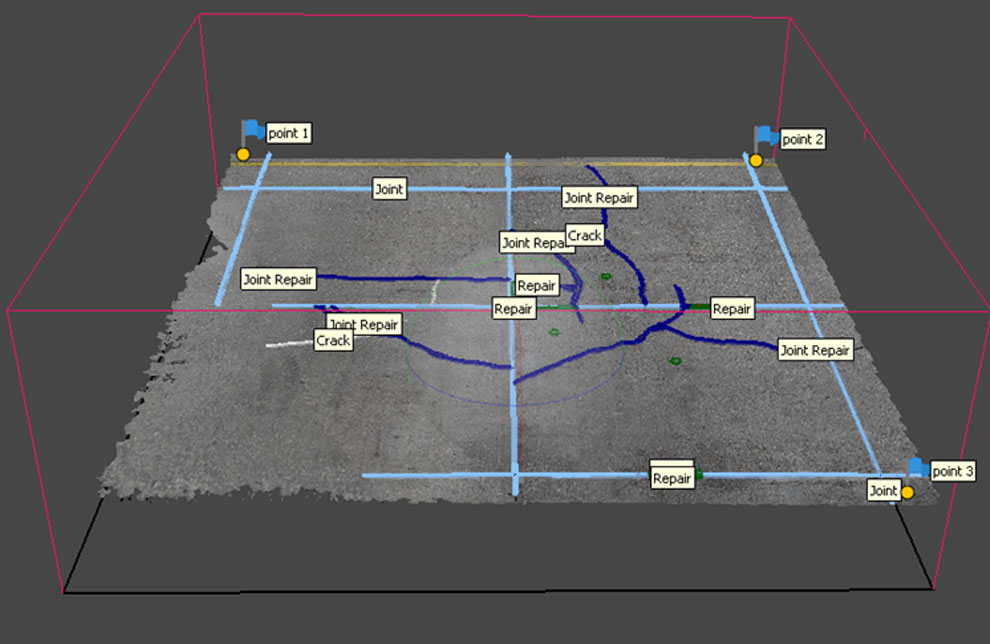

During the trial period, three different techniques were tested in combination with damage detection and classification based on Artificial Intelligence (AI). The Laser Crack Measurement System 2 (LCMS-2) was found to work much better with the damage detection algorithm than capture with regular cameras mounted on a drone or inspection vehicle.

As an airport, Schiphol is obliged to regularly inspect the runways, taxiways and aircraft stands and to determine a so-called Pavement Condition Index (PCI) score. If the score is too low, that particular runway or aircraft stand may not be used by aircraft as it is not safe enough. AI has often been used in the inspection of asphalt pavements, but so far this has not been possible for concrete inspections. The combination of LCMS-2 and AI damage detection offers the following advantages:

- We can carry out inspections both during the day and at night.

- We can inspect large surfaces faster.

- The extra costs for damage identification and classification are reduced to zero because it is done not by an inspector, but by AI.

- The inspection and assessment process, and subsequent rendering into a PCI report and geographical diverse information, is fully digital and automated.

- Results are less dependent on who carries out the inspection.

- The deterioration of an aircraft stand can be better assessed by looking at the development of normative damage over the years.

These advantages mean we can go from sampling inspection to 100 percent inspection. This eliminates the need for the manual maintenance inspection on the worst-scoring aircraft stands following the PCI inspection. In addition, we limit discussion and research surrounding any necessary maintenance measures. By discovering and repairing early damage much earlier, we also considerably extend the lifespan of the concrete pavement.

Read the previous blogs

-

Tap and go with your Digital Travel Credential!

Published on:Can you board and cross the border faster with a digital travel document? At the request of the EU, we are testing a DTC together with the government and KLM.

-

Test capturing ultrafine particles with droplets

Published on:We are working diligently to reduce the amount of ultrafine particles. A possibility is the use of water droplets to remove ultrafine particles from the air.

-

Autonomous Bus Initiative

Published on:Our ambition: operating the world's most sustainable and top-tier airports by 2050. With this in mind we're putting autonomous buses to the test on airside.