Crushing concrete sustainably

We’ve been doing it at Schiphol for years: crushing and grinding concrete rubble to make new concrete or foundation materials. Recently, however, we’ve been doing this is a lot more sustainably. This process now happens on-site and the new materials produced are reused at Schiphol.

60,000 tonnes of concrete rubble

Schiphol produces a considerable amount of concrete rubble every year. Around 60,000 tonnes of it to be precise. To put that into perspective, that’s the equivalent of around 9,000 elephants! All this concrete comes from construction and maintenance projects involving (among other things) buildings, the sewer system, runways and aircraft stands. The maintenance of our infrastructure is an ongoing process that continues throughout the year. Hence all that rubble. And we need a lot of concrete for all those projects too – around 10,000 tonnes each year.

Fewer kilometres and less CO2

Until recently, most of the concrete rubble was taken to a crushing facility in the local area. And for smaller jobs we rented a machine. That’s now a thing of the past. As a result, we have significantly lowered CO2 emissions and transport mileage. Around 80,000 km per year in fact, which is equivalent to two laps around the earth. This makes a nice contribution to our goal of being emission free by 2030.

Recycling facility powered by electricity

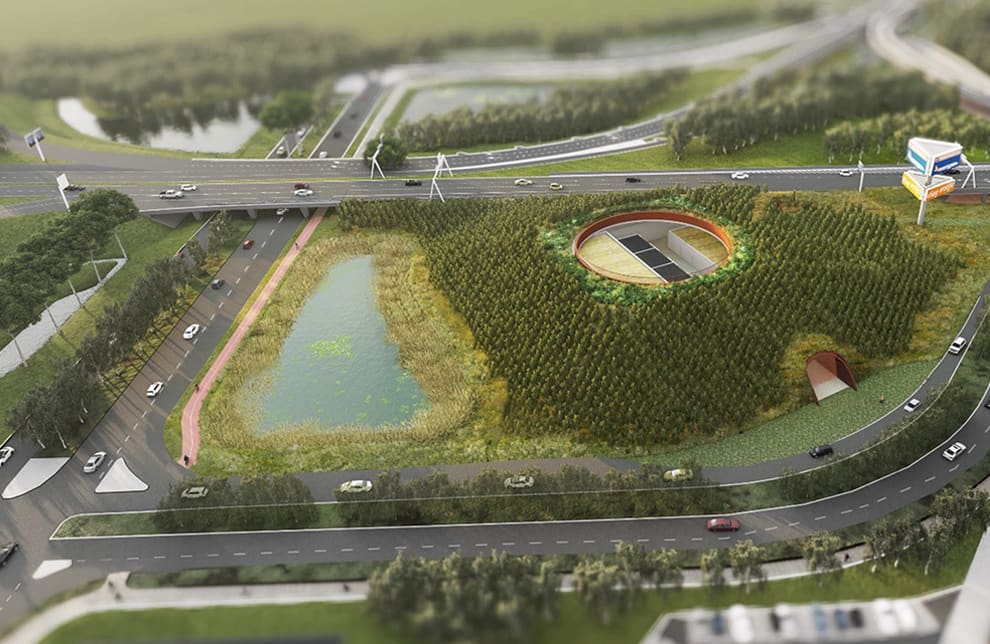

The concrete recycling facility is located on Zonnekruidweg, in the direction of Badhoevedorp, and is the size of two football pitches. It can easily be recognised – and from quite a distance – by the enormous yellow and white installations. It is in these installations that the concrete rubble is transformed into new concrete products. They will soon run on electricity and therefore no longer on diesel like the installations outside of Schiphol. This again will save emissions and contribute to our objective of being zero emission by 2030. Fun fact: the foundation of the site is made from reused rubble from Schiphol.

Full circle with recycling

What do we do with all the material produced at the plant? We reuse it at the airport for construction and maintenance projects. This way, we come full circle. And that is in line with our goal to be zero waste by 2030. The facility was officially opened in October, but has been running since the end of June. The foundation of the new Pier A was produced here, for example. This is how Schiphol is becoming a more sustainable airport, step-by-step.

Curious about how the concrete recycling facility on Zonnekruidweg works?

Read the previous blogs

-

Special high-voltage substation

Published on:New high-voltage substation contributes to one of Schiphol’s most significant sustainability goals: zero emissions in 2030.

-

More electric equipment

Published on:Most diesel generators have now been replaced by electric ones. Schiphol provides almost all planes parked at the gate with electrical power.

-

Start construction circular checkpoint

Published on:For the new checkpoint we are using material left over after the demolition of three office buildings and three cargo buildings at Schiphol.