Circular solution for PFAS-containing soil

What to do with the soil containing PFAS that we have stored at Schiphol in temporary storage facilities? We can of course dispose of the soil, but we would much rather choose a circular solution that fits our zero-waste objective. After almost two years of research and testing, we think we have found that solution.

The search for a sustainable solution

We have purchased a large soil treatment facility that will clean the PFAS-containing soil at our own location starting next autumn. This process results in 80% cleaned, reusable sand and 20% contaminated residual sludge. We are also now at an advanced stage in the baking of bricks from the remaining contaminated sludge. When heated at very high temperatures, the PFAS compounds disintegrate. This has the potential to be a great sustainable and innovative solution for the 'forever chemicals' in our soil.

PFAS: a problem that crosses borders

PFAS (per- and polyfluoroalkyl substances) have been widely used worldwide since the sixties, for example in firefighting foam and dirt-repellent coatings. They are now partially banned, because they hardly break down and can have a negative effect on the environment and health. However, PFAS is found in the soil in many places in the Netherlands, including at Schiphol.

Soil treatment facility for PFAS soil

Over the years, a lot of construction work has taken place at Schiphol where PFAS-contaminated soil has been released. We have now found a circular solution for that soil. We recently purchased a soil treatment facility. It works according to a commonly used technique, but with an adapted cleaning process especially for soil containing PFAS. To make sure it works for our own contaminated soil, we did extensive testing – both lab tests and complete cleaning trials – together with soil institutes. And the results were positive.

80% clean sand for reuse

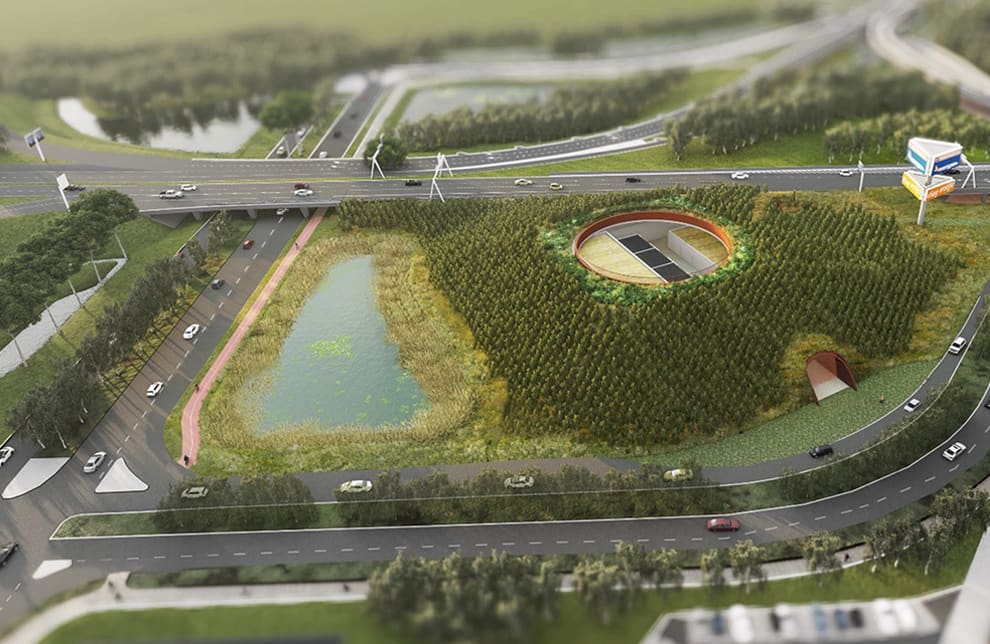

If the permit applications for the soil treatment facility are approved, it will be placed next to the Zwanenburgbaan, on one of the former temporary storage sites, starting autumn 2024. In three years' time, it will clean our soil so that 80% cleaned sand remains, which we can reuse in projects at Schiphol.

Bricks made of residual sludge

After cleaning the soil, 20% PFAS-contaminated sludge remains. We also went off the beaten path for a sustainable solution for this. We carried out a trial with a start-up called Claybens that is working on the development of bricks made from PFAS-contaminated clay soil and sludge. The theory is that, due to high and prolonged heating, the PFAS compounds disintegrate and disappear from the bricks. This may sound simple, but it's not. Over the past year, we have jointly gone through a whole process of testing this. In the process, an independent laboratory monitored the PFAS content in both the bricks and the flue gases. The results so far are promising.

'Circular dream'

When the upcoming larger-scale brick tests are also completed positively, we can start real production with the residual sludge from the cleaning process. The 'circular dream' is to use these bricks again at Schiphol in new projects. If we succeed, we will remove PFAS completely from the chain and use the products that this produces on our own site.

More about PFAS

Read the previous blogs

-

Cleaner fresh air

Published on:Indoor climate in stationary aircraft no longer controlled by kerosene-powered auxiliary engine, but by electrically-powered PCA.

-

Super battery being tested at Schiphol

Published on:Schiphol is the first airport with a special battery for extra electricity storage. Greater supply is needed for all the electric equipment.

-

Special high-voltage substation

Published on:New high-voltage substation contributes to one of Schiphol’s most significant sustainability goals: zero emissions in 2030.