Greener grass

The grass has started to grow again. And that means mowing! But what do you do with all those clippings? If, like Schiphol, you want to recycle all waste, you cannot simply send everything to a landfill site. You'll have to come up with a better way to deal with your cut grass.

From expense to asset

Schiphol has come up with a sustainable solution. It turns out that there is more to a blade of grass than meets the eye. Moreover, this solution provides the opportunity to earn money from cutting the grass, instead of it only costing money.

2000 football pitches' worth of grass

Let's talk numbers. How much grass is there at Schiphol? There is around 1000 hectares – almost as much as 2000 football pitches – of grassland around the runways. The grass needs to be cut 7 times per year to keep it at the right height. Each time the grass is cut (which takes 3 weeks!), 5000 tonnes of grass cuttings are produced.

Zero waste in 2030, circular in 2050

If you add up all the grass cuttings from every season, you end up with many tonnes of cut grass every year. Schiphol aims to be a zero-waste airport in 2030 and fully circular in 2050, so a sustainable solution for all these grass clippings was needed. Schiphol therefore teamed up with ECOR, a company that presses fibre panels under high pressure. This can be done using all kinds of fibres, including grass.

An MDF replacement

What can you do with ECOR panels? Basically, make the same products as you would from MDF panels, just with more sustainable material. ECOR panels are 100% bio-based, do not contain chemical agents and are 100% recyclable. They can be used to make all kinds of products, including ceiling panels, partition walls for constructions sites and furniture.

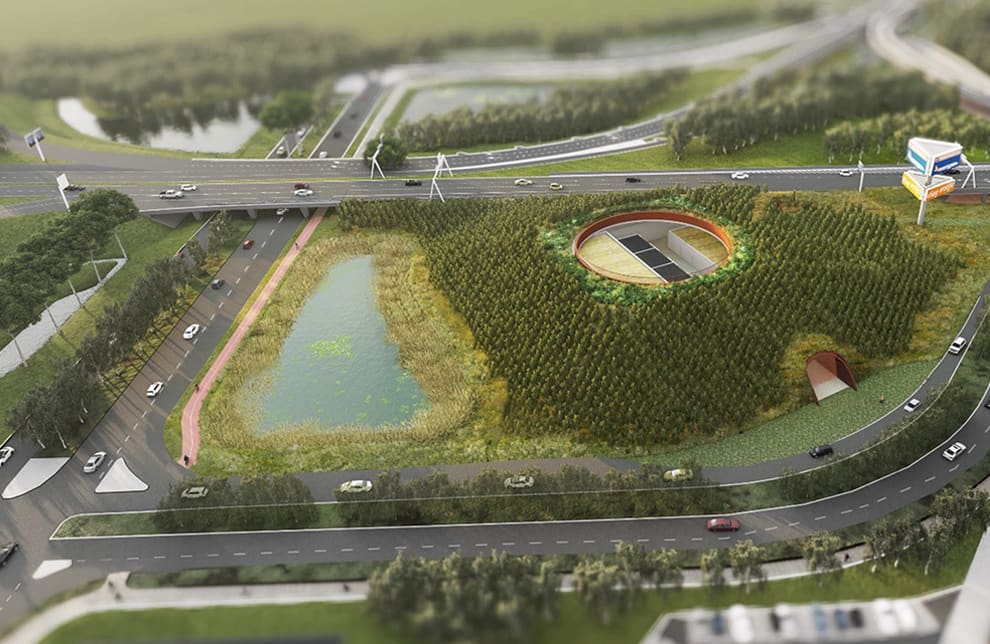

First load of grass cuttings for ECOR

Schiphol will soon be getting down to business. In June, the first load of grass cuttings from our runway area will be going into a special pit where it will be cleaned. Before the 5000 tonnes of grass can be processed, all traces of chemicals, such as kerosene, must be removed. That’s because ECOR only presses panels using clean and pure fibres. The first panels made from Schiphol grass are expected to come off the assembly line later on this year. In total, 100,000 square metres of panels will be produced this year.

Grass as building material at Schiphol

The panels will be used to make construction materials, which will go back to Schiphol. Our partners in construction will then use them in various building projects. And that’s not the end of this grass’ story. When a ceiling panel or partition wall comes to the end of its useful life, it goes back to ECOR. They then use it to press new panels, from which new products are made. And so the grass at Schiphol is even greener.

Read the previous blogs

-

Cleaner fresh air

Published on:Indoor climate in stationary aircraft no longer controlled by kerosene-powered auxiliary engine, but by electrically-powered PCA.

-

Super battery being tested at Schiphol

Published on:Schiphol is the first airport with a special battery for extra electricity storage. Greater supply is needed for all the electric equipment.

-

Special high-voltage substation

Published on:New high-voltage substation contributes to one of Schiphol’s most significant sustainability goals: zero emissions in 2030.